In the realm of heat treatment, the precision and efficiency of a furnace can make all the difference. Muffle furnaces, with their ability to isolate samples from direct flame or heating elements, have become indispensable in both laboratory settings and industrial applications. Among the myriad of muffle furnace manufacturers, Harrier Enterprises stands out, particularly for those seeking high temperature muffle furnace manufacturers.

Understanding Muffle Furnaces

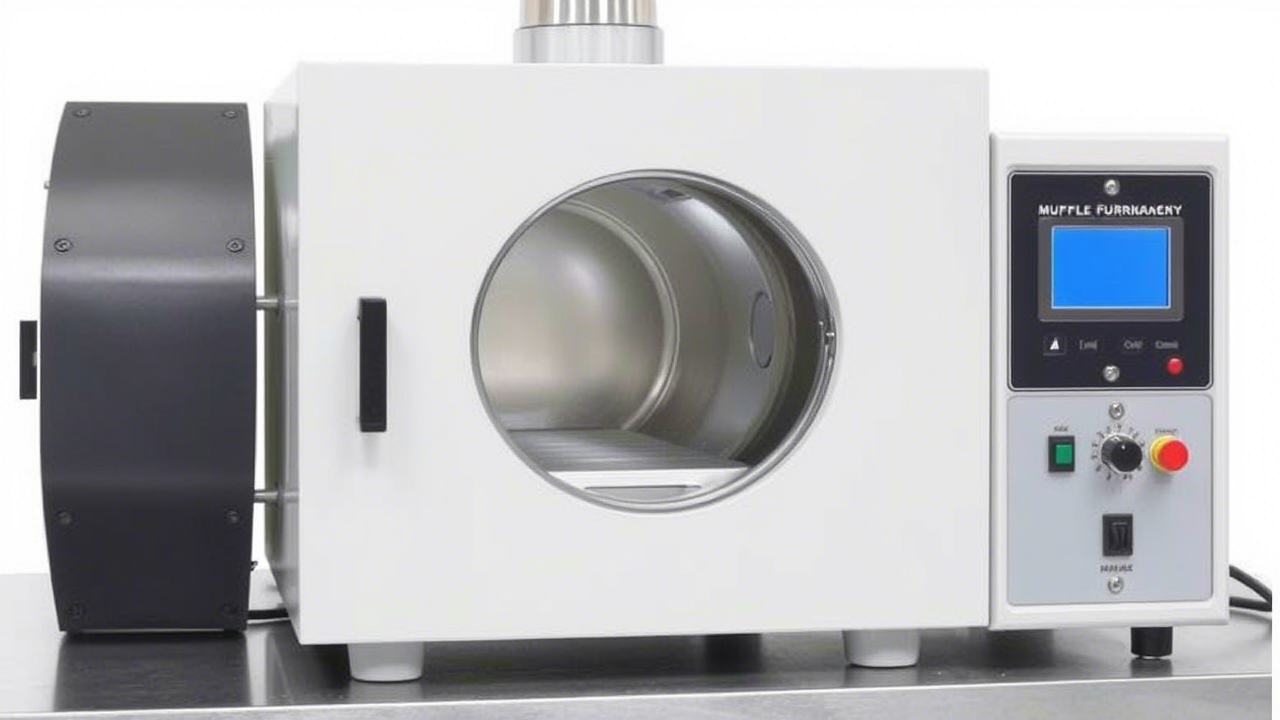

A muffle furnace is essentially an oven used for high-temperature applications where samples need to be heated in an environment free from direct contact with flames or the furnace's heating elements. This setup is crucial for ensuring uniform heating, which is vital for processes like annealing, ashing, and sintering. Harrier Enterprises has mastered the art of creating furnaces that not only reach high temperatures but also maintain precision in temperature control.

Why High Temperature?

High-temperature capabilities are essential for several reasons:

- Material Testing: Evaluating how materials behave under extreme conditions.

- Ceramics Production: Firing ceramics requires temperatures often exceeding 1000°C.

- Metallurgy: For processes like melting, sintering, or heat treatment of metals.

Choosing the Right Muffle Furnace Manufacturer

Selecting a muffle furnace manufacturer involves more than just comparing price points; it's about reliability, technology, customization, and after-sales support. Here's why Harrier Enterprises should be on your radar:

- Innovation: Continuous R&D to meet the evolving needs of industries.

- Quality Assurance: ISO certifications ensure compliance with international standards.

- Customization: Furnaces tailored to specific applications or client needs.

- Support: Comprehensive after-sales service and technical support.

Applications of Muffle Furnaces by Harrier Enterprises

Harrier's muffle furnaces serve a broad spectrum of applications:

- Laboratory Research: For material characterization, thermal analysis, and sample preparation.

- Industrial Production: From small-batch to mass production of ceramics, glass, and metal components.

- Educational Institutions: Supporting academic research and teaching in engineering and materials science.

Case Studies

Case Study 1: Ceramic Production - A leading ceramics manufacturer chose Harrier's high-temperature muffle furnace for its ability to uniformly heat large volumes, resulting in a 20% increase in production efficiency and a notable decrease in energy consumption.

Case Study 2: University Research - A prestigious university's materials science department utilized Harrier's furnace for experiments involving high-temperature reactions. The precision and reliability of the furnace contributed to groundbreaking research in new material synthesis.

FAQs

Maintenance Tips for Muffle Furnaces

- Regular Cleaning: Remove ash or residues post-use to prevent buildup.

- Check Seals: Ensure door seals are intact for optimal performance.

- Calibration: Regularly calibrate temperature controls for accuracy.

- Inspection: Look for any signs of wear or damage in heating elements.

- Professional Service: Schedule periodic professional maintenance checks.

Conclusion

Choosing the right high temperature muffle furnace manufacturer like Harrier Enterprises not only ensures you get a product that meets your technical specifications but also guarantees long-term reliability and support. Whether you're in the thick of industrial production or the meticulous world of scientific research, Harrier's commitment to quality, innovation, and customer satisfaction makes them a top choice for your heating needs.